Product

Continuous washing machines and washing machines, dishwashers for mechanical engineering

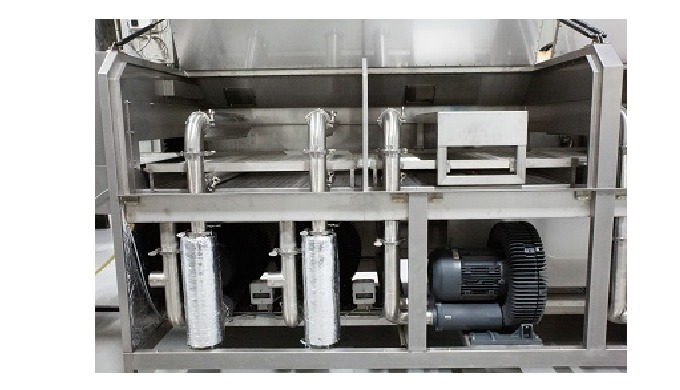

Continuous washers of machine parts are used in metal machining, machining of castings, processing of sheet metal and pressed parts. We manufacture washing and degreasing machines in many designs according to customer needs. These are mainly the following products:

- water-based washing machine of machine parts

- washing machine of parts for degreasing and phosphating

- Washing machine for cast iron workpieces

- washing line for aluminum castings

- washing machine for preserving weldments

- degreasing machine for pressed parts

- washing machine parts after polishing

- washing machine for gears and shafts

The machines manufactured by us meet all standards of ecological operation, they are made of high-quality stainless steel, equipped with modern elements, an exchangeable nozzle system, simple operation and maintenance.

More information about the complete range of washing machines for mechanical engineering, continuous washing machines and dishwashers of machine parts can be found at www.nerkon.cz

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

Conveyor washers This type of cleaning system is typically used decentralized in the production to wash parts continuously directly in the production line, so that handling of the parts between machining centers and cleaning systems is avoided. This is especially relevant for mass production of uniform parts in connection with punching, turning and similar production methods. Throughput washers can be used both for washing between different stages of the production, where subsequent production processes require that the parts are clean, or as a final cleaning before packaging or quality control of the parts. All our conveyor cleaning systems are offered with spray washing, rinsing and drying depending on the task and can be offered with a wide range of extra options such as filter systems. We have two types of throughput or conveyor washers, which are found in this category where the washing process is basically the same but the handling of the parts itself is different: Beltline is our robust belt-conveyor washer with spray washing, where the parts are placed on a belt, a chain or an parts fixture during the cleaning process depending on the task. This cleaning system is suitable for most types of parts and handling is gentle during the cleaning process. Beltline is also offered with ultrasonic cleaning if necessary to clean complex parts. Drumline is our robust drum washer with spray washing, where the parts move into a drum, which is usually fed directly from the machining centers. The cleaning system is offered both with stainless drum, plastic drum or a specially developed drum depending on the task. A drum washer is distinguished by being able to wash a large volumes of parts, but the range of parts suitable for a drum washer is more limited. If you want to hear more about our cleaning systems with conveyor and drum then you are welcome to contact us for further information, otherwise you can read more about this type of cleaning system under each product.

-

This is our chamber washer with 360°rotation of the basket during the cleaning process, in addition when having sensitive parts, it is possible to run a washing program with tipping or standstill of the basket. This cleaning system is very suitable for washing small complex parts in baskets, since it is most often not necessary to position the parts during the cleaning process, as well as to wash large complex parts such as hydraulic blocks or similar. This cleaning system is modular, so you can have it as an all-in-one solution where both washing, rinsing and drying are carried out in a chamber. Alternatively, each individual process is offered in several chambers, so we get separated the wash and rinse water and thereby minimize cross-contamination and significantly reduce the process time depending on the application. This type of cleaning system can be offered with both spray washing, ultrasonic cleaning, hot air and vacuum drying in a single chamber or multiple modules. All our Rotoline cleaning systems are manufactured in Scandinavia and functionality and quality are paramount, which is clearly reflected in the capacity of a total of 150 kg per basket. This robust construction ensures that you also have a well-functioning cleaning system for many years to come, and we are with you all the way so that the equipment is serviced correctly. Rotoline cleaning systems are offered with 1-8 modules and tailored to your task so that you always achieve the desired result and adhere to your cleanliness requirements in production all year round. You are very welcome to contact us for more information or read more on the product page.

-

Anmasi, spraywasher In this category we find in our spray washers with frontloading and toploading which today is widely used in the industry for a multitude of different tasks. If you are looking for a spray washer with conveyor, these can be found under the product category conveyor washers, where you can experience our series of conveyor washers and drum washers. The spray washers with toploading and frontloading are referred to as 1-chamber cleaning system where you place the parts on a stainless-steel platform or in a basket and then close the lid and the washing process starts. Cleaning the parts takes place in our spray washing systems in two different ways: The toploader series comes with a fixed nozzle system where the basket rotates via a gear motor during the washing process and in combination with our unique flat jet and point nozzle system is cleaning the parts. The frontloader series comes with a rotating nozzle mounted at the top and bottom of the chamber, which is cleaning the parts which are positioned in the middle of the chamber on a platform. Regardless of which of the above cleaning systems your looking for, we guarantee that with our cleaning system you will always achieve the best possible result with this type of machine. In addition, we offer both toploading and frontloading systems with washing, rinsing and drying depending on the application. Whether you’re looking for a toploader or a frontloader is determined by your needs and depends on the size of your parts and how you want to operate the equipment in your production. This type of cleaning system mostly being used to remove oil, grease and lubricants from parts related to production or maintenance. It’s very suitable for large components and it’s a very universal cleaning system suitable for most applications.

-