Product

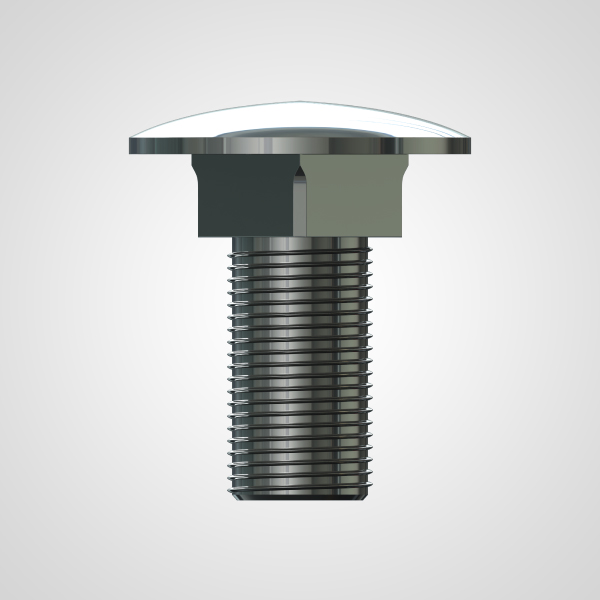

Cold Forged Fasteners

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

Buy Long Radius Bends from Renaissance Fittings & Piping Inc., the best Manufacturer, Supplier & Exporter of Pipe Fitting Materials in India Our Long Radius Bends are precisely engineered to ensure smooth fluid flow, minimal pressure drop, and superior mechanical strength in complex piping systems. Designed for high-performance applications across multiple industries, these bends are manufactured using premium-quality materials and advanced forming techniques to meet international standards like ANSI/ASME, MSS, DIN, BS, and JIS. Specifications Standards: ANSI/ASME, MSS, DIN, BS, JIS Pressure Ratings: SCH 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS Compliance: NACE MR 01-75 compliant options available Custom Fabrication: Bends can be manufactured to exact customer drawings and technical specifications Test Certificate: EN 10204 / 3.1 Manufacturer Test Certificate provided Materials & Grades Stainless Steel: ASTM/ASME A/SA 403 (Grades: 304, 304L, 310S, 316L, 321, 904L, etc.) Duplex Steel: ASTM/ASME SA 815 (UNS S31803, S32205) Carbon Steel: ASTM A234 WPB, MSS-SP-75 (WPHY 42 to WPHY 70) Low Temp Carbon Steel: ASTM A420 WPL3, WPL6 Alloy Steel: ASTM/ASME A/SA 234 (Grades WP5, WP11, WP22, etc.) Nickel Alloys: Inconel, Monel, Hastelloy, Alloy 20 Aluminium: 6061 T6, 3003 H18, 6351 T6 Titanium: Gr 1, Gr 2, Gr 5, Gr 7, Gr 12 Available Types SS 304 / 316 / 310 / 321 / 317 / 347 / 446 Long Radius Bends Duplex & Super Duplex Long Radius Bends Inconel 600 / 625 / 718 Long Radius Bends Hastelloy C22 / C276 / B2 Long Radius Bends Monel 400 / K500 Long Radius Bends Titanium Gr 2 / Gr 5 Long Radius Bends Copper Nickel 70/30, 90/10 Long Radius Bends Alloy 20, ASTM A105, A350 LF2 / LF3 Bends Request Quotation: https://www.rfpindia.com/enquiry/

-

Buy Buttweld Fittings from Renaissance Fittings & Piping Inc., a Leading Manufacturer, Supplier & Exporter in India Our Buttweld Fittings are engineered for durability, high-pressure tolerance, and corrosion resistance—ideal for pipelines in oil & gas, petrochemical, power, and marine industries. Key Features: Standards: ANSI/ASME, DIN, JIS, BS Sizes: ½” NB to 48” NB | Schedules: SCH 20 to XXS NACE MR 01-75 compliant | Test Certificate: EN 10204 / 3.1 Custom sizes and shapes as per drawing/specs Available Types: Elbows, Tees, Reducers, Caps, Stub Ends Materials: Stainless Steel, Carbon Steel, Duplex Steel, Alloy Steel, Nickel Alloys, Copper Nickel, Aluminium, Titanium Applications: Oil & Gas, Petrochemical, Power Plants, Marine, Water Treatment 📩 Request a Quote: https://www.rfpindia.com/enquiry/

-

In our production we process wire (steel, stainless steel, non-ferrous metals and special alloys) with a diameter of 2 mm to 16 mm into solid, semi-hollow or hollow pieces. These special pieces can have a length of up to 100 mm and a head or neck diameter of up to 30 mm. Solid and semi-hollow parts The production of solid and semi-hollow parts is based on specific customer requirements. Depending on these, the geometries of the head and the holes of the articles are specially manufactured outside the usual indications of the DIN. Bushings and hollow parts The bushings are manufactured in different head and shaft geometries. Thanks to the manufacture in our multi-operation presses, significant savings can be obtained compared to turning parts. Threaded parts During the finishing process, internal or external threads can be made, mechanically or by chip removal. These operations are known as threading by rolling, turning or milling. Knurled parts Molded parts can be manufactured with radial or axial knurling. These knurles are incorporated in the course of stamping or in a subsequent mechanical process. Bolts Especially in hinges, bolts are used as a movable bonding element. In hinge assemblies, they serve as spacers between components. Ball joints We manufacture ball joints with different geometries (e.g. with hexagonal or round bases) that can be used for riveting, welding or screwing alternately. The production of this type of parts can be done by machining the head or using segment tools in our multi-operation presses to manufacture the head part directly. Special processes such as inductive ball hardening or thread locking can be performed at the customer's request. Metal - plastic parts Cold stamped parts are fed by robots and after injecting the plastic form a firm and perfect bond. Special Parts In our multi-operation presses, we manufacture special and development parts, which are made using the most advanced tooling technology. Special profile wires can be used or even eccentric geometries stamped.

-