Product

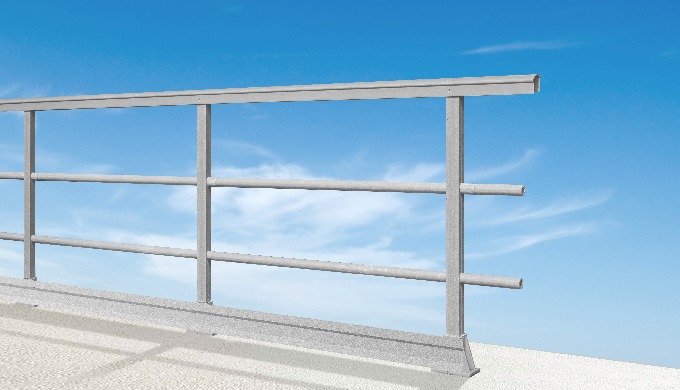

Garde-corps en polyester

Afin d’assurer la protection des usagers, JK Technic vous propose des profilés pour garde-corps réalisés en résine. Les garde-corps sont principalement utilisés en protection de passerelles industrielles et sont

équipés d’une main courante, d’une ou plusieurs lisses intermédiaires et de poteaux verticaux.

PRESCRIPTIONS DE SÉCURITÉ APPLICABLES AUX GARDE-CORPS

Un garde-corps doit être installé près des zones dangereuses où un risque d’enfoncement ou de passage au travers existe.

Par exemple, une passerelle d’accès à un extracteur sur un toit. Un garde-corps doit être installé dès que la hauteur de chute possible est supérieure à 500 mm.

Un garde-corps doit être fourni lorsque l’espace entre une plateforme et la structure de la machine ou mur est supérieur à 200 mm ou si la protection de la structure n’est pas équivalente à un garde-corps.

Toutefois, une plinthe doit être installée si l’espace séparant la plateforme de la structure adjacente est supérieur à 30 mm. La hauteur minimale du garde-corps doit être de 1100 mm.

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

At INPRE, we design and manufacture large fiberglass-reinforced plastic (GRP or FRP) components tailored to the specific needs of each client and industry. Our comprehensive production process covers every stage — from engineering and technical design to manufacturing, quality control, and final delivery. Examples of large GRP components we produce: Industrial fairings and technical enclosures Large-scale covers and structural enclosures Silos, tanks and storage containers made of GRP Structural panels and architectural elements Ventilation systems and industrial ducting Bodywork and components for special-purpose vehicles H2: Technology & Production Capacity Thanks to our specialized facilities and state-of-the-art equipment, we can manufacture large-format GRP parts using various processes such as hand lay-up, resin infusion, RTM (Resin Transfer Moulding), and contact moulding. Our multidisciplinary technical team ensures that all functional, regulatory and aesthetic requirements are met — from the initial concept to final delivery. H2: Industrial Applications of GRP Our large GRP components are successfully used in a wide range of industries, including: Chemical and petrochemical industries Renewable energy (wind, solar, hydroelectric) Urban and rail infrastructure Public works and water treatment facilities Transport and industrial bodywork Agricultural and livestock installations H2: Why Choose INPRE? Over 30 years of experience in composite manufacturing 100% custom solutions tailored to your requirements Technical advice from the design phase onward High production capacity for large-format parts Strong commitment to quality, innovation and on-time delivery CTA: Need to manufacture a large GRP component? Get in touch with INPRE and tell us about your project. Our team will assess your needs and provide you with the most efficient and reliable custom fiberglass solution. We manufacture quality. We design trust.

-

At INPRE, we specialize in designing and manufacturing large-scale GRP (Glass-Reinforced Plastic) components for the wind energy sector. We produce custom nacelle covers and hub housings for wind turbines, engineered for high mechanical strength, light weight, and durability in both onshore and offshore environments. Our end-to-end production process is optimized to meet the strict technical specifications of OEMs and key suppliers in the wind industry. H2: Why Use GRP in Wind Turbine Structures? GRP is the ideal material for external components of wind turbines due to its combination of structural performance and environmental resistance: Excellent mechanical and structural strength Lightweight — simplifies transport and installation High resistance to corrosion and harsh weather conditions Thermal and electrical insulation properties Long service life with minimal maintenance Freedom in design for aerodynamic and complex shapes H2: What We Manufacture INPRE produces a wide range of custom GRP components for the wind power sector: GRP nacelle covers Hub covers for wind turbines Monoblock or modular parts, depending on client requirements Protective and ventilation components Technical enclosures and outer structural elements We work either from client-provided CAD files or co-develop solutions with your engineering teams to ensure optimal integration, structural performance, and ease of assembly. H2: Why Choose INPRE? Over 30 years of experience in composite manufacturing Specialization in large-format GRP components for renewable energy Rigorous quality control at every production stage Capability to produce both high-volume and small production runs Facilities adapted for large and complex structures Commitment to sustainability and innovation H2: Who We Serve Wind turbine OEMs Tier 1 and Tier 2 suppliers in the wind power value chain Wind maintenance and retrofit companies Onshore and offshore wind projects CTA: Need Custom GRP Components for Nacelles or Hubs? Partner with INPRE for durable, lightweight, and fully customized fiberglass components engineered for the most demanding wind power environments. Tell us about your project — we’ll deliver the right solution. We manufacture quality. We design trust.

-

Protect your environment with our modular HDPE drum collecting platform! Highlights: Eco-friendly and safe solution: designed to solve contamination problems during drum handling, ensuring a clean and safe environment. Modular versatility: modular elements that are easily assembled, available in three dimensions to suit your needs: For 1 drum For 2 drums For 4 drums Convenient access: with a standard height of 115 mm, it allows easy access using a drum trolley. Grating options: available with plastic or hot-dip galvanised grating. Superior durability: treated against UV rays, ensuring a long life even outdoors. In addition, it is easy to clean, always maintaining its appearance and functionality. Flexibility and customization: the modular system allows you to optimize and modify the retention surface according to your needs, offering a tailor-made solution. Guaranteed tightness: stainless steel gasket ensures tightness and protection against spills. Key Benefits: Environmental protection: prevents soil and water contamination, contributing to sustainability and compliance with environmental regulations. Adaptability and growth: configure and expand your platform as your needs change, optimizing space and improving operational efficiency. Ease of use: designed for quick and easy access, streamlining drum handling tasks and reducing the effort required. Durability and resistance: high quality materials and UV protection guarantee a long life and resistance to adverse conditions. Simple maintenance: easy to clean, ensuring your platform stays in top condition with minimal effort. Available references: Ref. 52134: 1 drum model – dimensions: 710x675x115mm – retention volume: 35L – Allowable load: 75kg – HDPE mesh. Ref. 52136: 2 drum model – dimensions: 1230x625x115mm – retention volume: 35L – Allowable load: 75kg – HDPE mesh. Retention volume: 60L – Allowable load: 600kg - HDPE mesh. Ref. 52137: 2-drum model – dimensions: 1230x625x115mm – retention volume: 60L – Allowable load: 600kg - Hot-dip galvanised mesh. Ref. 52131: 4-drum model – dimensions: 1245x1245x115mm – retention volume: 120L – Allowable load: 1100kg - HDPE mesh. Ref. 52132: 4-drum model – dimensions: 1245x1245x115mm – retention volume: 120L – Allowable load: 1100kg - Hot-dip galvanised mesh. Ref. 52139: large side sealing gasket – dimensions: 1195x40x35mm Ref. 52176: small side sealing gasket – dimensions: 585x40x35mm Ref. 52138: access ramp for 60 and 120L platform – dimensions: 774x580x115mm

-