Product

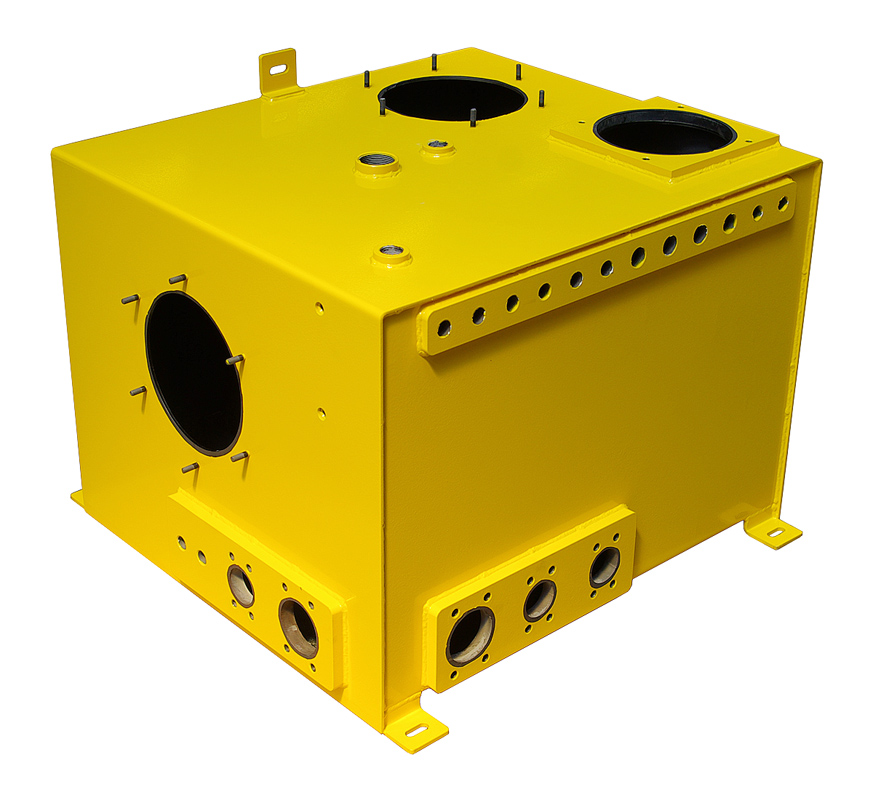

Scraper and waste container.

The tipping container serves primarily for storing chips from machine tools. For this purpose, the container is equipped with a double bottom with a sieve and a drain cock. The container can be transported manually by means of suspension lugs on a castor, fork lift truck or crane. When using a forklift truck, the tilting operation is performed automatically when the locking lever fitted with a transport lock is released.

The tipping chipping container is generally also suitable for storing another type of waste up to the maximum load capacity of the container.

Our chip and waste dumpster will help you to optimize your chip management.

For more information on the tipping container, visit www.dendera.cz

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

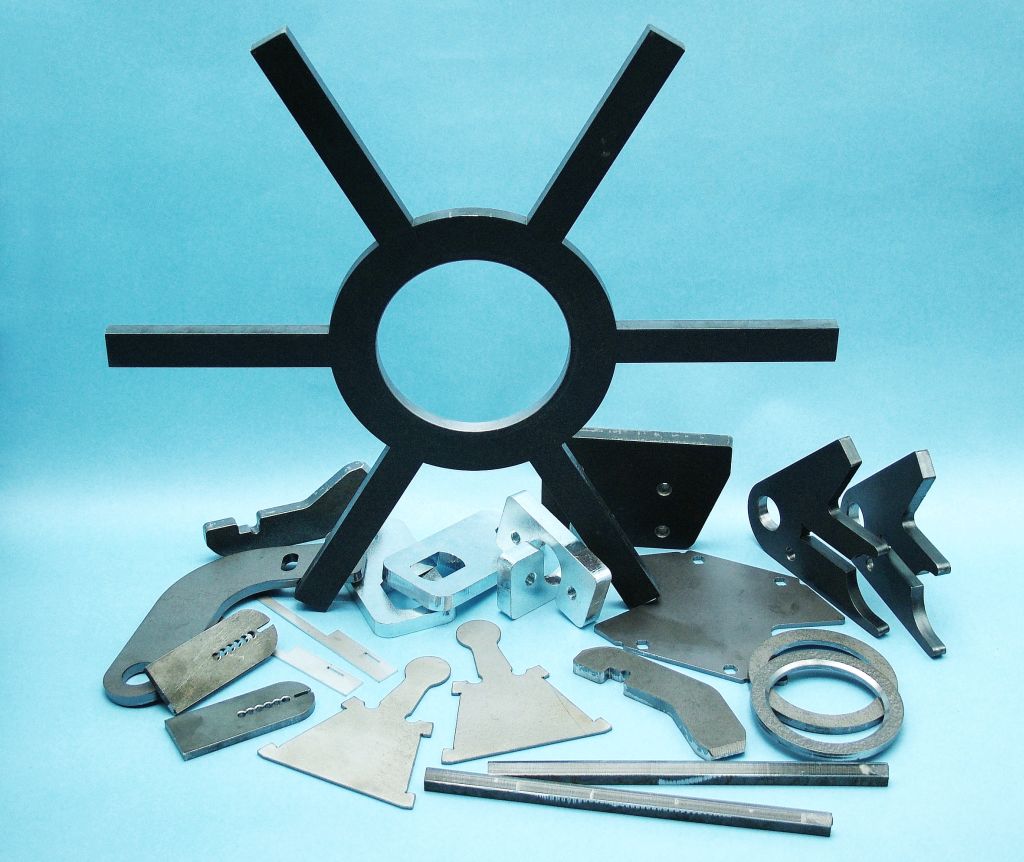

At Soluciones del Mecanizado Bian, S.L., we specialize in the machining of steel parts using state-of-the-art CNC technology. We manufacture custom precision components, fully tailored to the specific requirements of each client and industry. We work from technical drawings or physical samples, always ensuring the highest quality and reliability in every machined part. Steel is one of the most widely used materials in the industrial sector due to its mechanical strength, durability, and versatility. Thanks to our extensive experience, we work with a wide range of steels (carbon steel, stainless steel, alloyed steel, hardened steel, among others) and transform each material into functional solutions adapted to its final application. What do we offer in steel machining? CNC turning, milling, drilling, and threading of steel parts. Manufacturing of single parts, prototypes, pre-series, and full production runs. Technical advice on selecting the right type of steel according to its application (AISI 304, 316, 4140, F-114, among others). Option to apply heat treatments and special surface finishes (grinding, black oxide coating, galvanizing, etc.). Strict dimensional control and delivery of quality certificates upon request. Advantages of steel machining with Soluciones del Mecanizado Bian High precision in complex parts: thanks to advanced CNC machining centers and lathes. Speed and reliability: on-time deliveries, even for urgent projects. Professional finishes: clean, burr-free surfaces, ready for assembly or installation. Flexible production: from small components to large-format steel parts. Cross-sector experience: we serve industries such as automotive, machinery, energy, hydraulics, and rail transport.

-

Laser Cutting Service At Soluciones del Mecanizado Bian, S.L., we offer a high-precision industrial laser cutting service, ideal for processing both metals and technical plastics. Thanks to our state-of-the-art laser cutting equipment, we guarantee clean, fast cuts that meet the dimensional requirements of every project. Laser cutting is an efficient and versatile solution for the manufacturing of flat or semi-finished parts, whether for prototypes, short runs, or large-scale production. It is a non-invasive process that minimizes tool wear, speeds up production times, and delivers finishes ready for further machining, welding, or assembly. What does our laser cutting service include? Cutting of metallic materials: carbon steel, stainless steel, aluminum, brass, copper, and more. Cutting of plastic materials: acrylic (PMMA), polycarbonate, PVC, polyethylene, POM, etc. Thicknesses ranging from thin sheets to heavy-gauge formats, depending on the material. Custom cutting based on CAD files (DXF, DWG, STEP) or personalized designs. High repeatability in series production and precision up to ±0.1 mm. Possibility of combining with CNC machining, bending, or threading services. Advantages of laser cutting with Soluciones del Mecanizado Bian ✅ High precision: defined contours, clean edges, and burr-free results. ✅ Time and cost efficiency: fast, automated process with no need for tooling. ✅ Flexibility: adapted to parts of various sizes, shapes, and materials. ✅ Consistent cutting quality: ideal for repetitive series or components with critical tolerances. ✅ Integrated service: we combine laser cutting with machining, assembly, or surface finishing if needed.

-

🛠️ CNC Machining to Drawing – Precision According to Your Blueprint At Industrias Focs, S.L., we specialize in CNC machining to drawing, producing components strictly to customer-supplied technical drawings (DWG, DXF, PDF, etc.). Our workflow ensures compliance with exact specifications, tight tolerances, and flawless finishes for both prototypes and serial production 🔍 What Is "Machining to Drawing"? Machining to drawing means manufacturing parts exactly according to a client’s technical blueprint, without design alterations. The drawing serves as a contract, specifying geometry, tolerances, materials, surface finishes, and other critical data—ensuring a single, unambiguous reference for production ⚙️ Key Elements We Follow Our machining process strictly adheres to drawing standards: Orthographic views (front, top, side), plus detail/section views Precise dimensions and tolerances based on customer requirements Material and finish specifications as indicated in the drawing Additional notes (heat treatment, coatings, critical features) explicitly followed 🎯 Benefits of Our Approach Perfect compliance: parts manufactured exactly as drawn, avoiding costly rework or redesign. Streamlined communication: drawing-based process that eliminates ambiguity between design and production Consistent quality control: metrology checks against drawing dimensions from first article inspection to final batch delivery. Scalable production: ideal for single prototypes as well as large batch manufacturing with consistent accuracy. 🏭 Suitable for Diverse Industries Our machining to drawing service caters to sectors that require high precision and compliance to engineering specs: Machine tools & automation equipment Automotive & rail Food processing & hygiene equipment Energy, lighting, and metal infrastructure 🧩 Why Choose Industrias Focs? High-tech equipment: CNC lathes, milling machines, grinders, wire EDM—capable of machining diverse materials. Certified quality system: ISO‑based traceability and process control. Engineering support: we review your drawing to advise on optimal machining strategies and avoid ambiguities. Rapid response: quote requests in under 24 hours and efficient lead times tailored to production volume. 📈 Enhance Your Production with Accurate Drawing-based Machining Rely on us for on-point manufacturing: Eliminate guesswork: we work strictly to your drawing specifications. Minimize scrap and rework with accurate machining the first time. Scale manufacturing from prototype to series with confidence. 📩 Need parts machined strictly to your drawing? Contact us today for a no-obligation quote. Our team will review your files (DWG, DXF, PDF) and ensure perfect machining conformity from start to finish.

-