Product

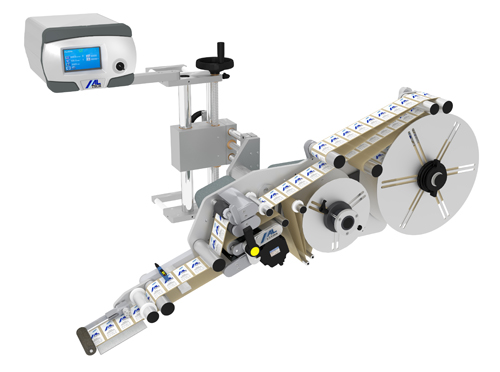

Self-adhesive label applicator - ALstep

The ALstep can hold label rolls up to 300 mm diameter for a long operating time; it is equipped with a separate control box with cooling fan, which makes it possible to operate it in harsh industrial environments.

Price of the Product

3

products -

ALTECH S.R.L.

Our recommended products and services

-

-

![Warehouse management Software: Integrates Stores Warehouse management Software: Integrates Stores]()

For the warehouse management of raw material and finished product of any type of company and sector.Integra-Warehouse is the perfect solution that Macsa provides for the management of warehouses raw material and finished product of any type of company and sector.All operational logistics, inventory management and warehouse tasks are performed in real time using radio frequency terminals and barcode reading, providing a high degree of optimization and quality in all processes.The system communicates directly with the rest of the modules Integrates Macsa that allows precise synchronization and continuity of all the processes that are developed in the company: reception of raw material, storage, production, encoding, packaging, storage, dispatch, traceability, global (ascending and descending).

-

![System of marking for packaging: MacsaJet Duo HR System of marking for packaging: MacsaJet Duo HR]()

Printing at high resolution gives you the quality, flexibility and reliability you need.Up to two printheads ProSeries of high resolution or eight print heads, up to 5 cm of height of impression each one.The Marksman Duo of FoxJet is able to operate with up to two printheads ProSeries of high resolution or up to eight print heads, valve up to 2” (5 cm) of height of impression each one. The color touch screen LCD provides the user a clear interface WYSIWYG for easy operation.implicidad is the term that defines this controller “intelligent”. It is designed for printing double-sided.Modular design impeccable.Controls a pair of printheads ProSeries of high resolution or valve of injection.QWERTY keyboard.Color touch screen LCD.Diagnostics and system status 24 hours a day, 7 days a week.Stores up to 500 messages.Ports of communication Ethernet, Serial and USB.Password protection.

-

HOW MANY FINGERS ARE INVOLVED IN THE PROCESS OF CODING AND MARKING FOR YOUR PRODUCTION? WITH OPTIMA ONLY UNOEn an encoding process involving many people performing multiple manual operations. Thus, two lines of production with three teams per line and 3 changes of batch or product per day, generating over half a million keystrokes (human interventions) per year which is more than half-a-million chance of error. To prevent this, Macsa has created Optima, a software bundled that centralizes the whole process of coding and tagging at a single point by drastically reducing the number of interventions.OPTIMA PROVIDES:• Easy deployment• Coding without errors• Integration with most ERP's• Traceability in the coding process,• Obtaining real-time information from the lines.Benefits from the first díaResultados OperativosOPTIMA minimizes the errors in the processes of encoding, generating direct savings in:- Incidents of small impact as, for example, waste and re-work.- Incidents of great impact such as the loss of public image, relationship with customers, logistics costs, etc OPTIMA reduces and simplifies the tasks necessary for the implementation of the odificación decreasing:- Times of change.- Direct costs of operation.Functional outcomes• Centralization and control of the entire process in a single point.• Traceability of the contents of the pallets.• Query and report production by date, shift, product and batch.• Historical information of incidents and situation of the equipment marking.

-